24V

5W

530

NATURAL WHITE

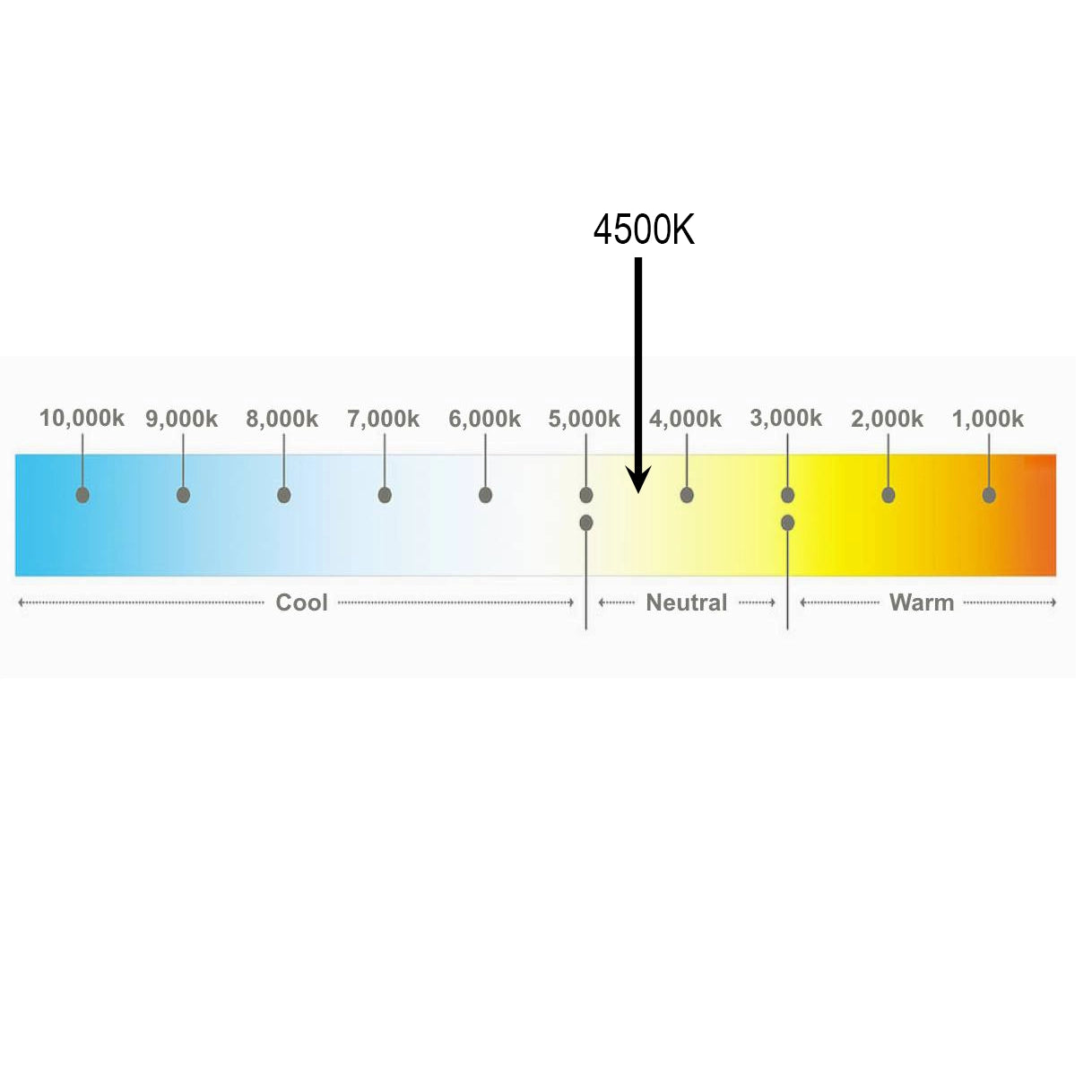

4500K

113

20

60

3M TAPE

3 YEARS

>80

EXTERNAL

10 mm

3 Oz

83.33 mm

Natural White Strip light 4500K, 24V, 5 W/ m, 530 Lum / m, 4500K, IP20, constant current, 20 meter roll

Natural White Strip light 4500K, 24V, 5 W/ m, 530 Lum / m, 4500K, IP20, constant current, 20 meter roll

Low stock: 2 left

SKU:CC60DIP20-10MM-5W-NW4500K

Couldn't load pickup availability

On Clearance, Last few left

24VDC, IP20, constant current strip, 530 Lm/meter. 60 pcs 2835 Epistar SMD chips per meter. A 20 meter length will need a 150 Watt constant current driver to operate. Constant current strips are not prone to big voltage drops, and are suitable for longer runs. Comes with 15cm wire on one end and 3 years warranty.

Dont forget to order 150W constant current driver to operate this strip.

This strip is suitable for Halo indirect lighting. Long run strips come very handy when the installation does not allow for strip to be powered every 5 meters.

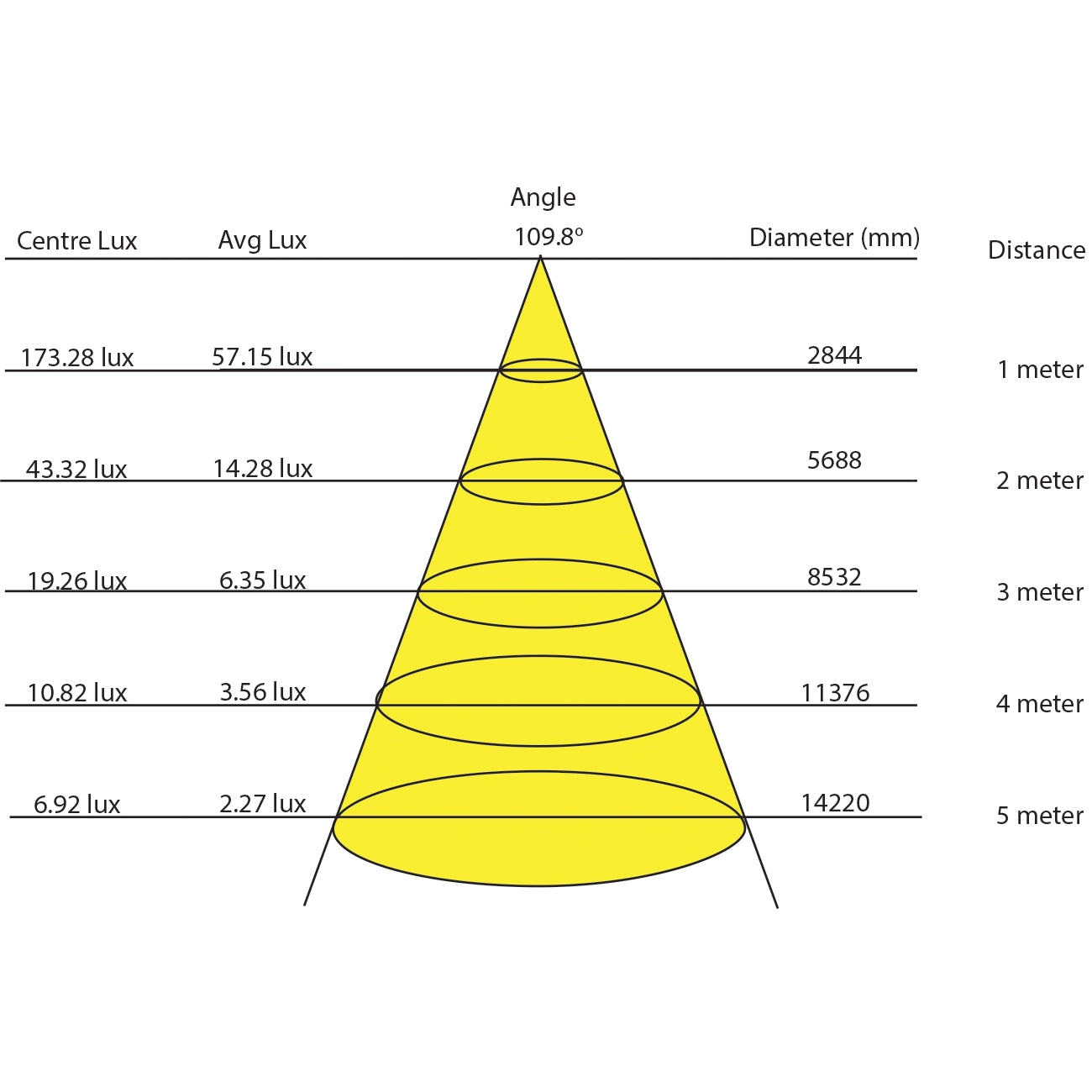

Disclaimer: The luminous intensity distribution diagram is based on actual readings taken from one strip light in the range and calculations used to produce the diagrams for all other strips in the range. The actual readings could be higher or lower by 2%

Share

Your project starts with choosing the right strip

Not all strips are made equal. Your first step is to buy the right products for your project. Start

with a strip with the highest number of LED’s per linear meter. Higher number of

LED’s per linear meter diffuse very well, even in relatively shallower Aluminium

profiles. The last thing you want is, to buy a cheap strip from your local hardware

store and then seeing all these hot spots in the end product. Green Lighting

has a no compromise policy on the number of LED’s per linear meter. As soon as

our suppliers announce that they have developed a strip with higher density of

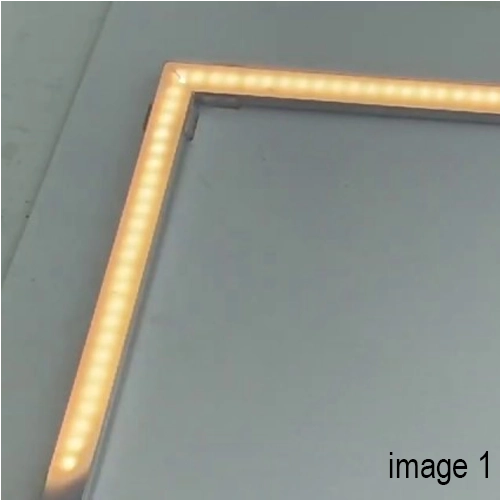

LED’s per linear meter, we are the first ones to order. The previous less dense strip goes on clearance sale. Not diffusing an LED strip in Aluminium extrusion is a totally no-go area. There is only one word to describe non-diffused LED strips; "Ugly". Its not very hard to get

a reasonably good outcome if you choose a high density strip. A low density strip can still give hot spot, despite diffusion. Have a look at image 1, an example of low density showing hot spots despite diffusion.

I ll just buy a COB strip, problem solved… or is it ?

COB stands for Chip on Board. We are not going to go into the manufacturing details here. COB strip lights do have a lot more light sources per linear meter. There is a few points

to remember though a. At this point in time, SMD strips are still more efficient,

(more lumens per watt) and in general carries better colour rendering index b.

Remember that an RGBW SMD 5050 or 4040 chips have all the 4 colours (Red, Green, Blue and White) on each SMD chip. SMD 5050 chips are 4 in 1 Chips, all 4 colours are built on the same chip . A112 LED/meter strip will have 112 (4 in 1 Chips) of each colour per linear meter. If a COB chip says 480 LED’s per meter, it would effectively mean that it has 120 LED’s of each

colour. c. At this point in time, SMD strips are superior in Colour rendering index rating and colour consistency rating. With more development in COB technology, we may see a shift in this trend in coming times.

Choosing the right Aluminium profile

You have chose the strip with the highest density. The next step is to choose the right Aluminium profile, both to serve the architectural needs and the diffusion. We will leave

the architectural decision to you, as you know best how you want your strip

lights to look. We are here to help you choose the Aluminium profile to give

you the right diffusion and maximum light output. The deeper the aluminium channel, the

more diffused your light will be and less hot spotting you will get. So why not choose the

deepest channel, and solve the problem. While a deeper channel solves the

diffusion problem, it reduces the effective light output of the entire

installation. Sometimes the desired outcome is to have both diffusion and maximum light output. It could be in a scenario where the strip lights is to be used as work light. Quite a few architects have started specifying strip lights a the only source of light source in certain locations. In these installations, diffusion and the effective light output of the strip light installation both become very important. To solve the problem, go for the highest LED’s per linear meter, the highest lumen output strip and the shallowest Aluminium extrusion that could do the diffusion.

The good news is that our 240D strips are so dense that even our shallowest Aluminium channel; AL-BT-K1708 diffuses it perfectly well without sacrificing the effective light output substantially.

Yes I am in, how do I put it together?..

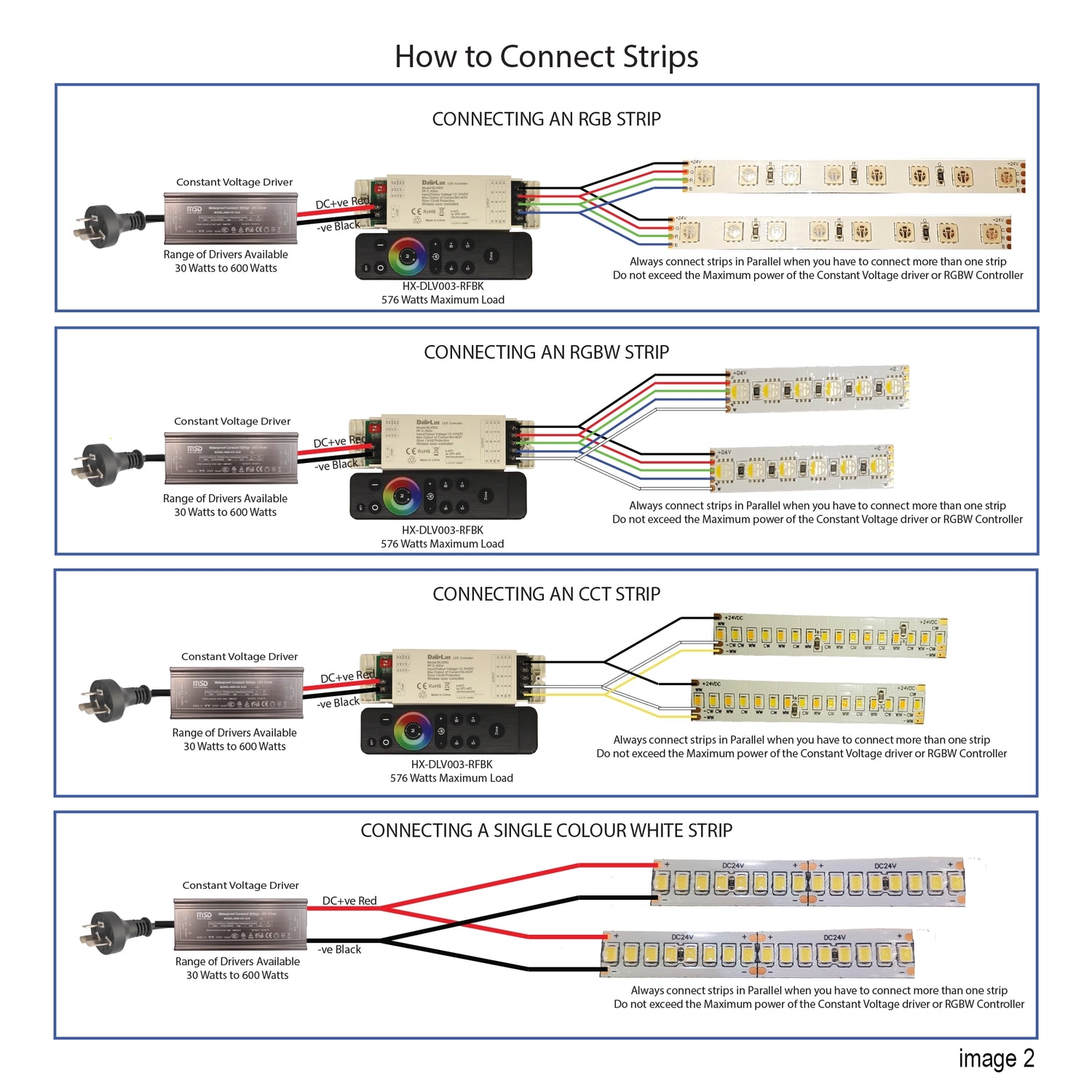

Strips would usually come with a 150mm tail attached to its one end. Simply follow the

instructions in image 2 .There are a few basic principles you must follow:

- Calculate the total power your installation is going to need. Multiply the total length of the

strip(in meters) by the power rating per meter. This will give you the total

power of the strip. Now increase this number by 10% to allow some head room for safety. By doing this, you will prolong the life of your driver and the entire system. You can

get this number as follows: Power of strip per meter x Length of strip in meters

x 1.1 Once you get this number, choose the driver that is rated for a wattage equal to or

more than this number. If it exceeds the maximum rating of the driver and controller, it will eventually burn them out. Example: Strip rated at 18W per meter, 5 meter length

(18 x 5 x 1.1 = 100W , a 100W driver would do fine for this installation)

- Always connect DC+ to DC +. This is usually the black wire on the RGB, RGBW, 3CCT strips. On single colour white strips, (or single colour blue, red or green strips), its usually the Red that connects to the DC+Always connect strips in parallel.

- Do not try to power strips by connecting strips in a daisy chain. This will result in voltage drop and the strip that is further away from the driver may show colour inconsistency or less lumens.

- Constant Voltage can only run 5 meters in one run. Any longer runs will result in voltage drops at the non powered end. You have to re-power every 5 meters. Make sure the connection is made in parallel as shown in image 2

Your strips are expensive.... I don't want to pay so much for it

Expensive is a very relative term. The price of a strip is pre-dominantly determined by the number of LED's per meter, the colour rendering index and the density of its PCB. Green Lighting makes no compromises in these areas when choosing its product line. If you are comparing our strips to the ones you get from your local hardware store, its a very unfair comparison. Our strips are guaranteed to perform even in the most demanding set ups like commercial fit outs a. Our strips have a higher LED/Linear meter density, a higher CRI and a much higher light output. Our strips will give you a linear outcome with colours that pop. They are designed for customisation, hence why we do not sell DIY packaged strips with the driver and controller built into a small little wall brick. Imagine if you were to do an installation where you have to cut the strip into two pieces. The question you have to ask yourself is, how are you going to power the second piece of strip. Not all installations are in one straight line using a single piece of strip light. We say if you buy our strips, it might hurt on the day you pay for them, but not afterwards. Its not going to be one of those strips that show a different colour of light at the powered end and a different one at the far end. At the end of the day the centuries old rule applies; you get what you pay for!

Strips that come with a driver and controller built into a small brick smaller than your phone charger should raise alarm bells for reliability. Even our smallest driver (30W) weighs over a quarter of a kilo because it uses very high quality components that are designed to last 5 years, even in very demanding commercial installations.

In summary, if you factor in the warranty, the beautiful linear finish that pops, we believe we offer exceptional value for money.

Still not sure what to do and need more advice, have a chat to us..

We are an Australian brick and mortar high end lighting supplier based in Canberra. We love lighting and are very passionate about giving the right advice to our customers. If you are feeling unsure, you can message us anytime. We will try to get back to you within 10 to 15 minutes. If you would like to speak to us, please give us a call during business hours.

-

24V

-

5W

-

530

-

NATURAL WHITE

-

4500K

-

°

113

-

20

-

60

-

3M TAPE

-

3 YEARS

-

>80

-

EXTERNAL

-

10 mm

-

3 Oz

-

83.33 mm